FRP Fans & Fan Stacks for Cooling Towers, Mines & ACC Applications

Global supplier of energy-efficient industrial ventilation fans and FRP stacks for cooling, mining, and heavy industries

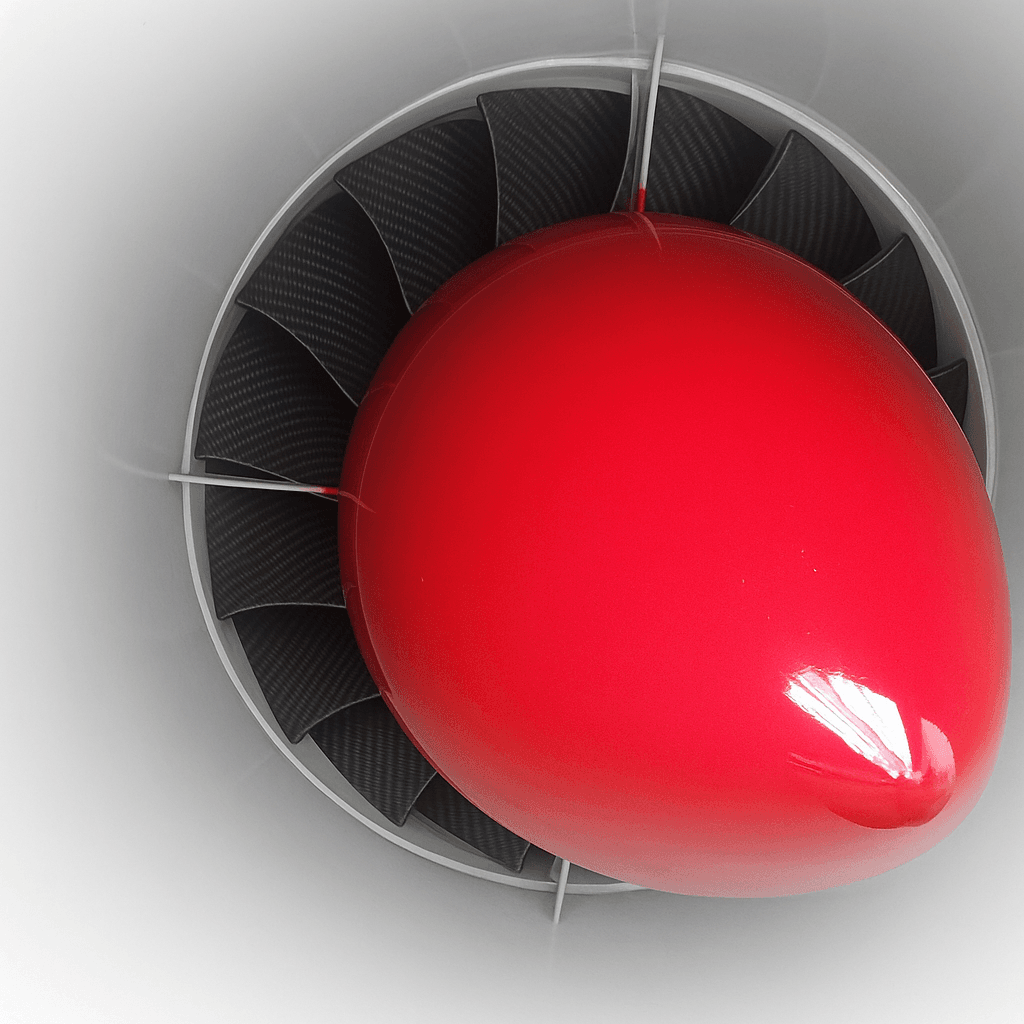

At Maya Fan, we specialize in designing and manufacturing high-performance FRP axial fans, ventilation systems, and fan stacks for industries across the globe. With over 100 innovative fan designs developed in the last decade, our solutions are trusted by power plants, mining operations, cooling tower OEMs, and large-scale infrastructure projects. Our fans are optimized for energy savings, low maintenance, and extreme operating conditions, backed by in-house wind tunnel testing and advanced engineering. Maya Fan History

Our Core Industrial Fan Solutions

We have three major parts of our business:

Project Supply to OEM

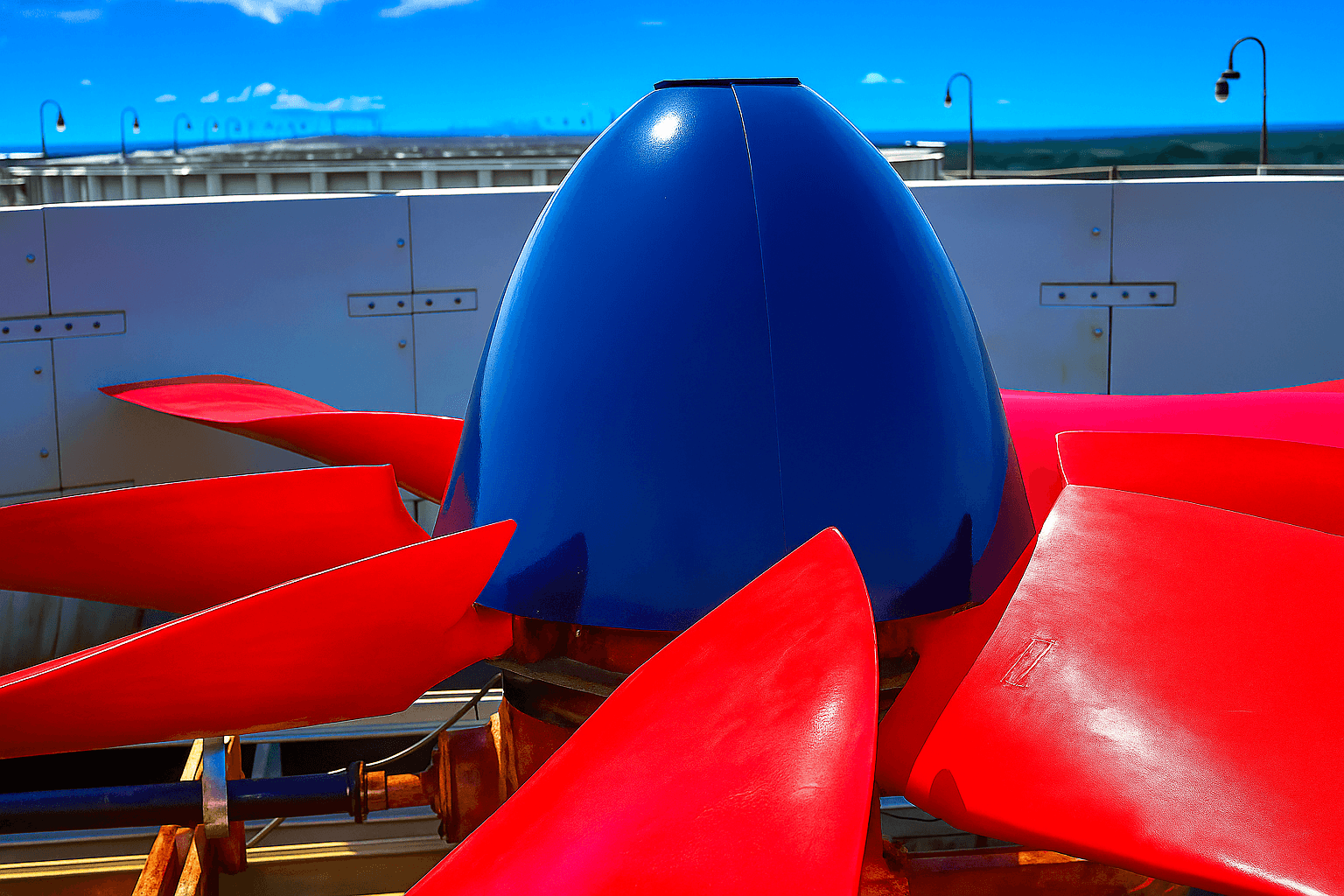

We supply high-performance fan systems for OEM applications, including Cooling Tower Fans, Air Cooled Condenser (ACC) Fans, and FRP Fan Stacks Learn more about our OEM Fan System Solutions.

OEM Supply

We are one of the leading fan suppliers to OEMs in India.

Our product range includes fans for cooling towers, fans for Air Cooled Condensers (ACC), FRP fan stacks, and other customized fan solutions for industrial applications.

Our list of OEM clients includes many of the industry’s major names, such as:

Fans A.S.

SPIG Cooling Towers

B&W

- AS – CT

- NEXT Cooling

- Holtech

- HAC

GEA Cooling Towers

Enexio

L&T

BHEL

Holtec International

Gammon Cooling Towers

AS Cooling Technologies

…and many more.

We are proud to be part of some of India’s largest and most prestigious projects, including India’s largest cooling tower and the ACC project for the world’s largest power producer, NTPC.

Executing Turnkey Projects

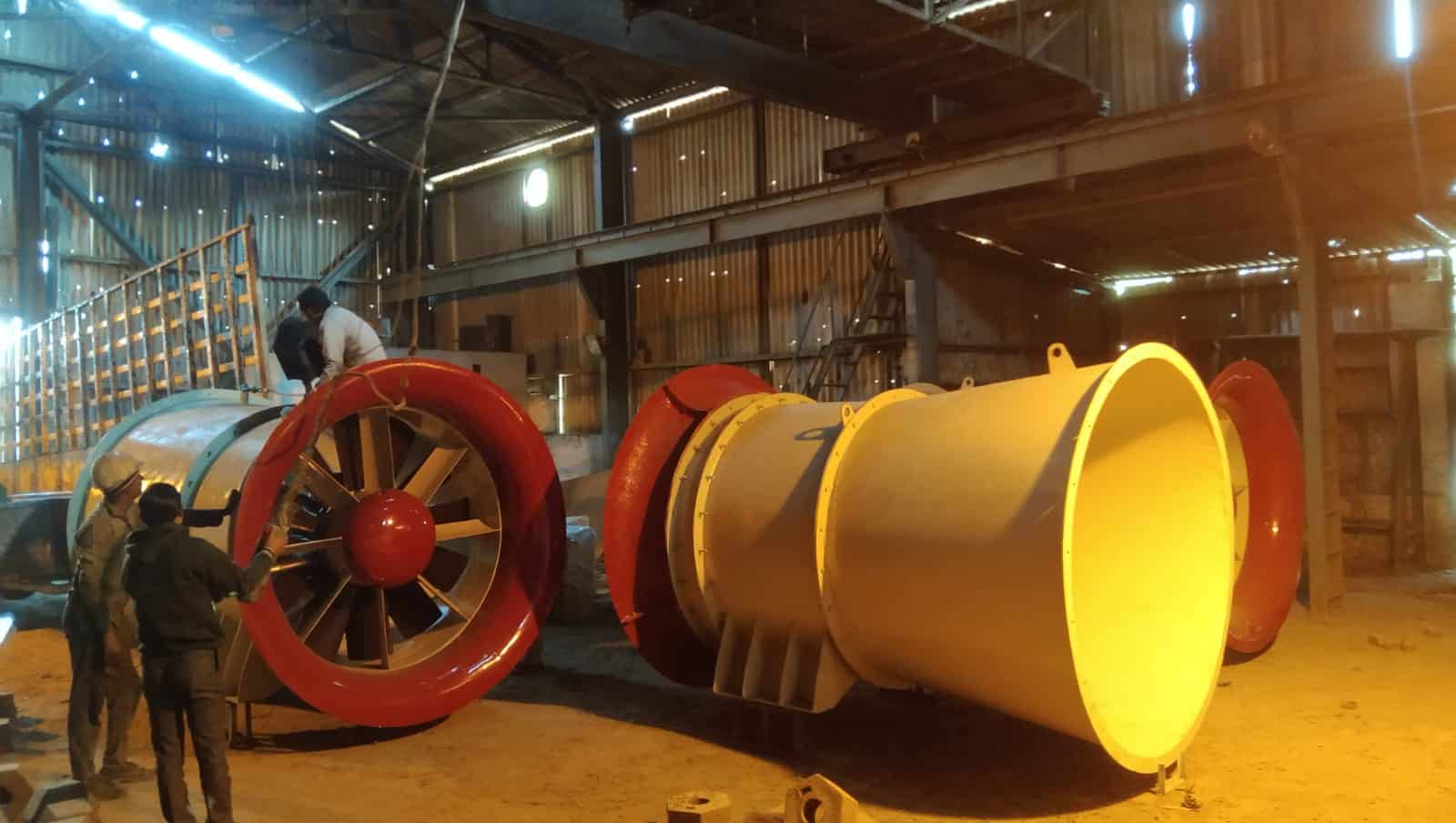

We undertake complete fan system projects for various industries, including Mining Ventilation Fans

Turnkey project

We offer a wide range of fan solutions, including some of the most critical applications — such as mine ventilation.

These fans must be robust and highly reliable, as they are vital safety equipment that directly impact the health and well-being of the underground workforce.

Maya Fan is India’s largest supplier of fans to the mining industry.

In just the past decade alone, we have supplied more than 700 mining fans for various projects across India.

We provide all types of mining fans, including:

Main Mine Ventilation Fans (Primary Fans) / Surface Fan

Auxiliary Fans

Booster Fans

Some highlights of our major mining fan projects include:

We made the single largest fan supply to SECL, delivering 117 fans in a single order.

We have also been one of the largest suppliers to several leading organizations, including SECL, MCL, ECL, BCCL, WCL, MOIL, OMC, HGM, HZL, UCIL, and many more.

Fan Upgradation

We provide fan upgradation solutions for higher efficiency and improved performance. Our upgradation services cover Cooling Tower Fans, ACC Fans, Mining Ventilation Fans, FRP Fans, HVAC Fans, and Humidification Fans and many more.

Upgradation

During its early years, Maya Fan Air Engineering Pvt Ltd focused extensively on undertaking critical projects aimed at power saving and performance improvement.

In many of these projects, we have proven power savings ranging from 10% to 45%. Even we are sometimes amazed when we see savings as high as 35%, 40%, or even 45% — figures that are rarely achievable under normal circumstances.

However, our practical results speak for themselves. The key reasons for these substantial savings are:

Over-designed fans supplied with the original equipment

OEMs lacking specialized knowledge in fan engineering

Use of non-optimized fans, often just copies of metallic fans designed for unrelated applications

Our fan upgradation projects typically aim to achieve:

Significant power savings

Performance enhancement

Capacity improvement through retrofitting.

AT Maya Fan We never force-fit our standard existing fan. We remain responsive to input design data and develop new products as and when required.

We keep adding the latest facility to remain updated with time. we do have our in-house wind tunnel for product validation.

We do provide breakdown emergency help with our ready-to-launch fan. We keep some standard fans ready at the plant which can be offered in case of emergency.

HCL MMV Fans

This Single Order Includes 3 Booster fans.

These fans are supplied with an FRP impeller.

Two recent orders include 6 MMV Fan, with this supply total fan in SECL reach to 171.

This Project includes 103 Cooling Tower Fans. Which is India’s largest single project supply.

NTPC North Karanpura

Supply of 270 sets of Air-cooled condenser fan Bell. Fan size 36-foot stack height 6 Foot.

Maya Fan emerges as India’s largest supplier in the field of industrial fans. Recently we have developed an entire series of next-generation fans. These new generation fans full fill the need for increased static pressure needs. It will have great efficiency and reliability, the Key feature of Maya Fans.

- Turnkey Solution for the project.

- Smart retro fitment with the least cost.

- Energy efficiency.

- Technical competency and resources for the tailor-made product solution.