MINING VENTILATION FANS / MINING FANS

Main/Surface Ventilation Fans, Booster Fans and Auxiliary Ventilation fans

Mining ventilation fans are crucial to the mine,

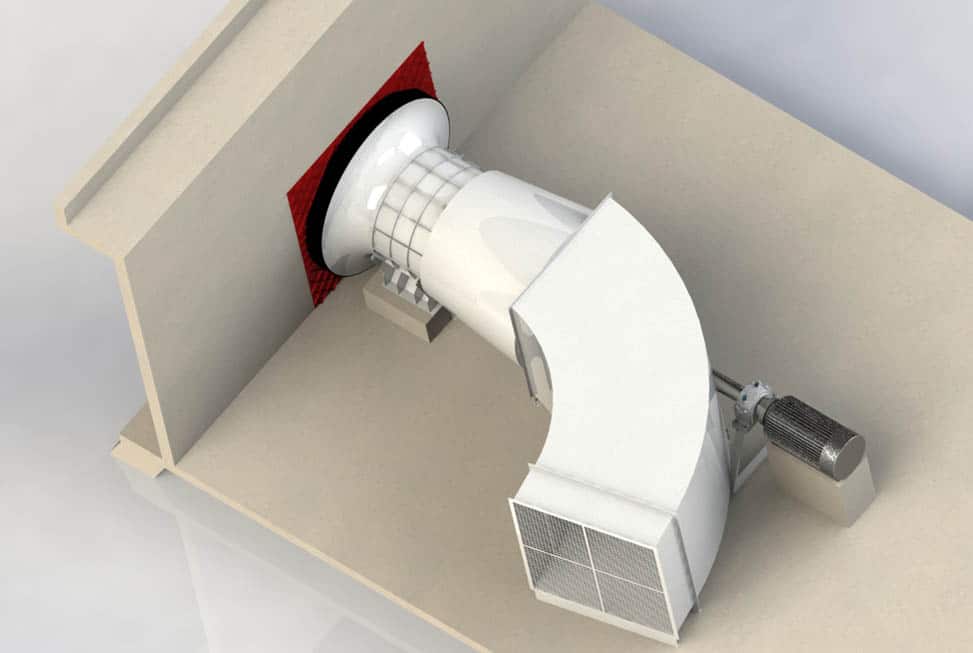

Installation

Up to 30% power saving

mm wg Static Pressure capacity

Up to Kw Rating

Types of mining ventilation fans

Mine Ventilation Fans are categories as main fan or surface fan, booster fans, and auxiliary mine ventilation fans. Below is the detail of these categories fans…

Main Fans

Main Mine Ventilation Fans

The main mine ventilation fan is a Large fan or combination of fans. It generates flow for total air requirements in an underground mine.

It ventilates the Main circuit of mine. So, it is term as “Main mine ventilation fans”. It is also known as a surface fan because it installed at the surface of the Mine (Not underground).

In an underground ventilation system, this fan is of critical importance. The occupational health and safety of employees working underground depend on it.

This main ventilation fan is so Critical, that in case of its shutdown. The instruction issued to declare emergency close all work and evacuates from mine.

Main mine ventilation fans are the Largest power-consuming equipment in the mine. Considering all these conduction Maya main ventilation fans are –

- Robust design and construction.

- Maintenance-free operation.

- At Maya, we provide remote monitoring of our main mine ventilation fan.

- High-efficient and low operating cost.

- Our Main ventilation fans are low speed and quiet in operation.

Due to the above feature. Our main mine ventilation fans achieve great success within a short time. And having installation in the following mine –

- Coal mine

- Manganese Mine

- Gold Mine

- Zinc Mine

- Hard-rock (metallic) mines ventilation

Auxiliary fans

Auxiliary Mine Ventilation Fans

Most of the auxiliary fans in mines are normal tube axial type fan and the maximum possible efficiency of tube axial fan is far less then aerofoil fans.

Considering the above fact at Maya fan we are manufacturing airfoil bladed auxiliary ventilation fan which is having very high efficiency.

Maya auxiliary mine ventilation fans are a single-stage fan and unlike double stage auxiliary fan in mine, the single-stage fan is much more efficient.

If we consider the same efficiency for single stage and double stage impeller then in double stage case we have to multiply the efficiency of both impeller thus resultant efficiency reduced significantly.

Light in weight as auxiliary ventilation fans operate in small branches of mine thus it is very important to have easy in handling, at Maya we made our auxiliary fan very robust yet so simple and handy that it can be handled in any of complicated location

Maya auxiliary ventilation is available in various material as –

- Anti-static fiber auxiliary ventilation fan for coal mine where aluminum is not allowed.

- Aluminum alloy fans.

- Steel blade for the environment where aluminum is not allowed and FRP is not sustainable like in case of very high tip speed requirement.

Booster Fans

Mine Ventilation Booster Fans

A mine ventilation booster fan is a primary fan that is installed in series with another primary fan.

Without the booster fan operation, the total mine airflow will fall significantly. Booster fans are typically installed as mine develops and primary fan no longer has the pressure or flow capability to service increased resistance of operation.

In this sense, the booster fan operates as an integral and “symbiotic” unit with the original primary fan to provide sufficient total airflow for mine.

Mine booster fans are technically main fans that are installed underground to maintain required airflow by overcoming the mine resistance.

Booster mine ventilation fans can reduce the pressure of the main fan and decrease system leakage and the total required air power.

A mines booster fan is an underground ventilation device installed in the main airstream (intake or return) to handle the quantity of air circulated by one or more working districts. It is installed to operate in series with the main fan and boost the air pressure of ventilation air passing through it.

Provision of additional air quality at strategic locations within the mine and separate from longwall split.

- Increased pressure to drive airflow into working splits-

- Reduction of intake to return pressure differential, out bye of the booster fan location

- Reduction in out bye leakage

- Reduction of main fan airflow requirements for a given in bye performance

- Optimization of power utilization

Key Feature of Maya Mining booster fans

- High efficiency – Latest airfoil

- Optimization for lower operating cost

- Higher safety factor – we prefer to consider the safety factors around 10.

- The robust construction of casing and diffuser.

- maximum utilization of composite material in Maya booster fans.

- compact design for the mine having space restriction for movement and installation.

MAYA FAN STRENGHT

CREATIVE IDEAS

AT Maya Fans we always remain creative to deal with the challenges in the field of tailor-made mining fans, so far we have developed fan for up to 400 mm static pressure that to in single-stage fan.

EXCELLENT FEATURES

We are the pioneer to introduce FRP corrosion-resistant fan in this critical application and installed more than 600 fans including all types of underground mining ventilation fans.

FULLY RESPONSIVE

AT Maya Fan We never force-fit our standard existing fans, but remain responsive to input design data and develop new products as and when it required.

MINE VENTILATION FAN DEVELOPMENT PROCESS

Every mine is different and having requirement of a customized fan so we do not Force customer to compromise with the standard available product and remain open for new development, this customized fans development process steps are as below –

FAN DATA COLLECTION

It is must-have accurate data (Fan duty point) for fan development so we do collect data on the field with our technical expertise and high-tech equipment.

FAN DESIGN

We analyze collected data and conclude for a specific design point as well as keep a range of operations in mind while developing a new fan.

VALIDATION

It is must validate each of the design outcomes to decide for the best solution, and we have full modeling and testing facility in the house.

PRODUCTION

Once the final fan design concluded, it is handed over to the production team for the preparation of tooling. To final launch this product

Mining ventilation Fans Key Feature

High Efficient fan impeller.

Low Operating Costs.

Low Operating Noise.

Long Life Construction.

Performance for All Seasons.

Low and cost effective Maintenance.

Zero Downtime with Maya mining fan.

Fast emergency response.

Why choose Maya mining fan?

Low Operating Costs

- Maya High efficient airfoil blade design

- optimization of twist cord and cross-section provide maximum efficiency.

- The involvement of the most advanced composite material reduces turbulence and produces smooth linear airflow.

- Optimum design for the duty point No oversizing of the fan.

Long Life Construction

- Most of the part made of Heavy-duty composite and hot-dip galvanized material which meets the corrosion resistance and equipment life requirements of your most demanding heavy industrial applications while still delivering an outstanding value.

- Lightweight impeller, therefore, increases in the life of all the mechanical components.

- Mining Fans are also available with Series 300 stainless steel as an optional upgrade which comes with a 5-year limited warranty.

- Maya mining Fans are manufactured in ISO-2015 certified facilities, attesting to our commitment to comprehensive quality processes and systems.

Fast emergency response.

- Ready-made fan available.

- The minimum stock of the fan spare is maintained.

- Low manufacturing time because of zero outsourcing.

- An expert team available for fan installation.

Quiet by Design

- the composite blade has a glossy surface finish that offers smooth airflow.

- low tip speed design (Nose are directly proportioned to tip speed).

- No outsourcing full quality control thus achieves minimum tip clearance.

- Special design available for extra low noise fan which can reduce noise up to 10 dba compares to conventional fans.

Performance for All Seasons

The fan is a constant flow machine and to maintain its performance despite critical variation in weather Maya mine ventilation fans are designed for a broad range of operations our fans are having a good amount of reserve margin for both airflow and static pressure fan performance throughout the year in all type of seasons.

Low Maintenance/Less Downtime

- Maya FRP mine ventilation fan is made of high-quality material and robust design.

- Maya design fan for low operating tip speed which increases overall system life and also reduces the chance of failure.

- Unlike the painted fan, we do provide a permanent coating of a gel coat which remain an integral part of the fan blade body and does not get separated due to erosion.

Maya mine ventilation fan construction

Here is the list of Maya mine fan component with a there brief detailing

Fan Blade

Maya mine ventilation fan blade is made of latest airfoil similar to that of airplane wing we do choose most advanced airfoil possible for the fan to provide maximum efficiency by this only we have achieved superior performance which is far ahead in the mine ventilation fan industries, our blade is very robust in construction and designed for 7-10 times of operating load we also provide superior wear resistance material to maintain surface stability for a long period of time which prevent efficiency deterioration. recently we have developed a special series in mining fans in which we are providing state of the art fans in fiber reinforce plastic we are using this superior epoxy material for the blade tip speed of up to 22000 FPM

This FRP material is having some of the very charismatic property it is very much possible to produce any complicated shape with ease thus provide economical solution some of its special features are and listed below –

- High strength at low weight.

- Good impact, fatigue, and Tensile Strength (Ultimate)

- Excellent environmental resistance.

- Excellent chemical and corrosion resistance.

- Good thermal insulation.

- Better life of the entire ventilation fan system due to low assembly weight.

- Low moment of inertia help for the selection of optimum motor and reduce over design due to higher starting torque thus motor operate under a better range of efficiency.

Fan Hub / Boss

Hub used in mine ventilation fans are heavy in construction in this we are using heavy thickness mild steel plate, cast iron, or Aluminum clamp and stainless steel hardware to provide long life we are coating all mild steel parts with heavy thickness of zinc.

Note – Optionally we also provide customize hub/Boss on special demand of the customer, like caste hub boss, Spider Type Fabricated hub, etc.

Taper Locking

in most of our mine ventilation fan hub, we preferred to have a taper locking arrangement and this is provided with several types of different locking arrangements which are proven in the field these taper lockings are mostly made of Cast iron or stainless steel.

Fairing inlet and outlet

these are inbuilt component in mine ventilation fan, as in mining fan pressure remain high and air travel at very velocity therefore even small turbulence harness unnecessary energy so it is very must to have smooth airflow throughout the fan system and well design and construed inlet-outlet fairing contribute significantly, we at Maya fan make these fairing in composite material to provide smooth finish which helps to keep laminar uninterrupted flow through the fan system.

Inlet guide van

It is used to guide inlet air in such a way that it will inter in impeller at a particular angle so that it will have minimum losses for changing the direction of air under fan impeller.

Out Let guide van

Outlet guide vane are used to guide exit air in such a way that it will remain linear to the system with minimum turbulence in it. which will prevent eddies generation and minimize friction of air with the fan casing surface.

Silencer in mining fan

are used to minimize fan sound to a desired acceptable level. these mine ventilation fan silencers are designed to match with the shape of a fan and to have minimum pressure drop in it.

Fabrication of mine ventilation fans

mining fan is having a large component of fabrication starting from its main body to diffuser and many other parts these are required to have a good control there for it is manufactured under closed control of ISO system and are maintained as per Section IX, ASME

Unlock All Feature Of Mining Fan With Our Special Feature Presentation.

FEW OF OUR PRESTIGIOUS MINING FANS CUSTOMER

Frequently Asked Question

Type of mining in which Maya fan having its installation?

Following are the few major categories

- Coal mine ventilation fans.

- Manganese mine ventilation fans.

- Gold Mine ventilation fans.

- Fan for Uranium Mine.

- Fan for Copper mine.

- Underground iron mining fans.

These are not the only list we have the solution for any king of mine exists in mankind.

Which is a better axial fan or centrifugal fan in mining?

Airfoil axial fan is having maximum efficiency in fan industries and following are the brief difference between axial and centrifugal fans –

-

The axial fan is superior to deliver high airflow.

-

It required less power for similar operations compare to the radial fan.

-

It is compact in construction.

-

It is lightweight and simple in construction.

-

An axial fan is less expensive.

we can conclude axial fan is a better choice for mining ventilation.

Underground coal mine ventilation fans type and selection !

In underground coal mining, various hazardous gases emit and many of them are explosive and it is been derived from many mining accidents that high energy impacts of aluminum on rusty steel can cause a spark. Therefore aluminum bladed fans are banned in underground coal mining.

Coal mine ventilation use all three type of fan Main/Surface fan, Auxiliary ventilation, and booster fan.

So while selecting any of coal mine ventilation fans it should be taken care that underground fan should not have aluminum blade whereas for a surface fan it can be used.

What is the alternative of the aluminum blade in underground coal mining?

In general, steel is considered the only replacement for underground mining ventilation fans blade and by this either we need to compromise with less efficient propeller type fan or need to pay a high cost for CNC machined steel blade.

So at Maya, we have developed a series of auxiliary and booster fan in anti-static fiber which offers excellent efficiency and competitive in cost.

What is the parameter required to inquire for customized mining fans?

Following are the various parameter requirement for customized mining fan solution –

- The requirement of airflow.

- System pressure / Static pressure.

- Air density.

- Operating temperature.

- Diameter restriction if any !

- Installation Type (Forced draft or the induced draft)

- Reverse rotation requirement.