Axial Fan | FRP Fans | AirFoil Fans

The fan having airflow direction parallel to the axis of rotation known as axial fans.

Type of axial FRP fans

Tube Axial Fans

Tube Axial Fans have an axial impeller. This axial fan impeller operates inside a cylindrical housing known as fan cashing. Clearance between blade and cashing should be least to improve efficiency. In tube axial fan impeller runs faster to enable air delivery at high pressure.

Vane axial fans

van axial fan also having an axial impeller that runs inside cylindrical cashing. Additionally, the van axial fan has guide van to direct and align the airflow this increases fan efficiency.

With improved efficiency van axial fans have the capacity to handle higher static pressure. These vane axial fans are the most efficient in the industries.

Propeller fan

Propeller fans have low speed and low to medium static pressure. A large volume of air delivered by the propeller fans. The typical use of propeller fans is an indoor application as exhaust or ventilation. The efficiency of the propeller fan is low compare to tube axial fans and vane axial fans.

Application

Up to 40% power saving

mm wg Static Prassure capacity

Up to Kw Rating

Airfoil FRP fans

Fans use airfoil cross-section in its blade known as airfoil fans.

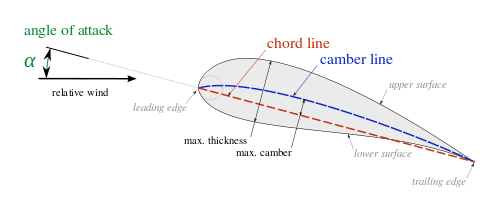

What is an airfoil?

Airfoil is a cross-section used in fluid mechanics to develop objects with a high lift to drag ratio.

Understanding airfoil –

- The upper surface – convex back surface of the airfoil fan blade is the Upper surface of the airfoil.

- The lower surface – Working surface of the airfoil fan blade deliver air is the lower surface of the airfoil.

- leading-edge – the thick edge of the airfoil which faces the incoming air in the fan.

- Camber – Convexity of the airfoil from leading to trailing edges called camber.

- camber line/mean camber line – it is the mean line of the airfoil considering the camber curve.

- Trailing edge – it is the thinnest rear edge of the airfoil.

- Chord line – it is the straight line from the leading edge to the trailing edge.

- Type of fan.

- Application of fan.

- The blade construction material.

- Blade weight restriction.

- Manufacturing processes.

These airfoil fan delivers high energy efficiency. Thin airfoil selected for the metallic blade. Because in case of metal weight of the blade increased with thick airfoils.

In the case of FRP bladed fans more freedom is available to the designer. As with hollow blade construction, any profile can be used with minimal impact on weight.

In the FRP blade, airfoil selection depends on the manufacturing process. These processes are Hande mould blade, RTM blade, Pultrusion blade, etc.

Airfoil blade terminology and definitions

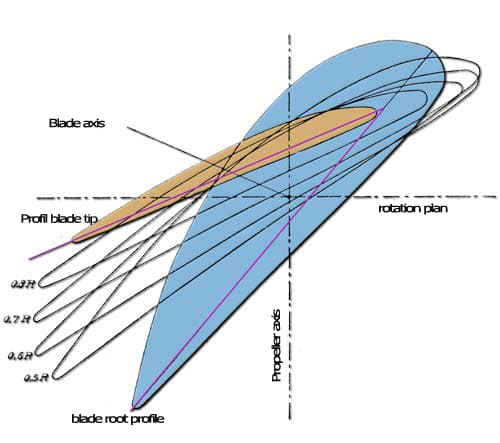

- Fan blade Span – Blade tip to root is the blade span.

- Fan blade Chord at the root – it is the airfoil chord at the root of the blade.

- Fan blade Chord at the tip – it is the airfoil chord at the tip of the blade.

- The leading edge of the fan blade – is the attacking edge of the blade that faces the first impact of incoming air.

- Blade tip speed – it is the leaner speed of the fan blade i.e. periphery of the blade multiplied by rpm.

- The angle of attack – it is the angle of the blade chord to the axis of rotation in the axial fan.

- Blade twist – it is the angle between the chord line of blade root and blade tip.

- Blade tip – it is the end portion of the blade it is having the highest speed.

- Blade route – it is the broadest portion of the blade.

- Blade shank – it is the portion of the blade that connects the root to the fan hub. It clamped at the hub and wears all the load of the blade.

Energy-efficient airfoil FRP fan blade

It is the blade Made of the most efficient airfoil for the application. width of the blade remains high at the root and decreases gradually toward the tip of the blade. The blade should have a twist to maintain constant air velocity from root to tip.

FRP fan blade

- FRP is the most suitable material for the fan blade.

- FRP blades are corrosion resistant and can use in steam moisture and even in an acid environment.

- FRP fan blade can be anti-static for the use of critical applications to pass the static charge.

- FRP enables hollow blade construction which gave freedom to choose the best airfoil.

- FRP having a high strength to weight ratio which enables the low weight of large fan blades like cooling tower fans and ACC fans.

- the use of a good UV additive FRP blade can achieve high ultra violate ray stability.

- FRP fan blade is easy to handle and install.

- With a high grade of resin improved abrasion resistance can be achieved.

- The surface finish of the FRP blade is far higher compare to any of the other material

What is FRP?

It is an abbreviation of Fiber reinforce plastic. To be more specific it is also called GRP glass reinforce plastic. Fiber is a general term it may be any fiber-like Glass fiber, Carbon fiber, Natural fiber, etc. But GRP is specific and it covers the broadest range of FRP.Energy-efficient axial FRP fans

It is a relative term that is why everyone claims for having there fan energy efficient. But to achieve the title of most energy-efficient axial flow fan it must have –

- An efficient airfoil should use in the fan blade.

- The fan should achieve the least tip clearance.

- The designer must have good knowledge of the fan application.

- Fan material should be able to operate in the working environment without deterioration.

- An energy-efficient fan should not be over-design or it will be less efficient at duty point.

- Also, fans should not be under design. as it will be better for efficiency but may not fulfill the airflow need.

Energy-efficient axial FRP fan blade Feature

Considering so many advantages of Energy-efficient FRP fans. we use them in following industrial application –

- Cooling tower fan FRP fan blade.

- Heat changer fan FRP fan blade.

- Air-cooled condenser fan FRP fan blade.

- Fin fan-cooled FRP fan blade.

- FRP blades for a mine ventilation fan.

- Exhaust and ventilation fan using FRP blades.

Why choose Maya energy efficent FRP fans?

Low Operating Costs

- Maya High efficient airfoil blade design

- optimization of twist cord and cross-section provide the greatest efficiency.

- The involvement of the most advanced composite material. It reduces turbulence and produces smooth linear airflow.

- Best design for the duty point No oversizing of the fan.

Long Life Construction

- Most of the parts made of Heavy-duty composite and hot-dip galvanized material. It meets the corrosion resistance and equipment life requirements of heavy industrial applications. while still delivering an outstanding value.

- Lightweight impeller, thus, increases in the life of all the mechanical components.

- FRP Fans are also available with Series 300 stainless steel as an optional upgrade. which comes with a 5-year limited warranty.

- Maya FRP Fans manufactured in ISO-2015 certified facilities. attesting to our commitment to comprehensive quality processes and systems.

Fast emergency response.

- Ready-made fan available.

- The minimum stock of the fan spare maintained.

- Low manufacturing time because of zero outsourcing.

- An expert team available for fan installation.

Quiet by Design

- the composite blade has a glossy surface finish that offers smooth airflow.

- low tip speed design (Nose are directly proportioned to tip speed).

- No outsourcing full quality control thus achieves minimum tip clearance.

- Special design available for extra low noise fan which can reduce noise up to 10 dba compares to conventional fans.

Performance for All Seasons

The fan is a constant flow machine. So to maintain its performance despite critical variation in weather, Maya FRP fans designed for a broad range of operations. Our fans are having a good amount of reserve margin for both airflow and static pressure. fan performance throughout the year in all types of seasons.

Low Maintenance/Less Downtime

- Maya FRP fan made of high-quality material and robust design.

- Maya design fans for low operating tip speed which increases system life and also reduces the chance of failure.

- Unlike the painted fan, we do provide a permanent coating of a gel coat. This remains an integral part of the fan blade body and does not get separated due to erosion.

Maya FRP fan construction

Here is the list of Maya FRP fan component with a there brief detailing

Fan Blade

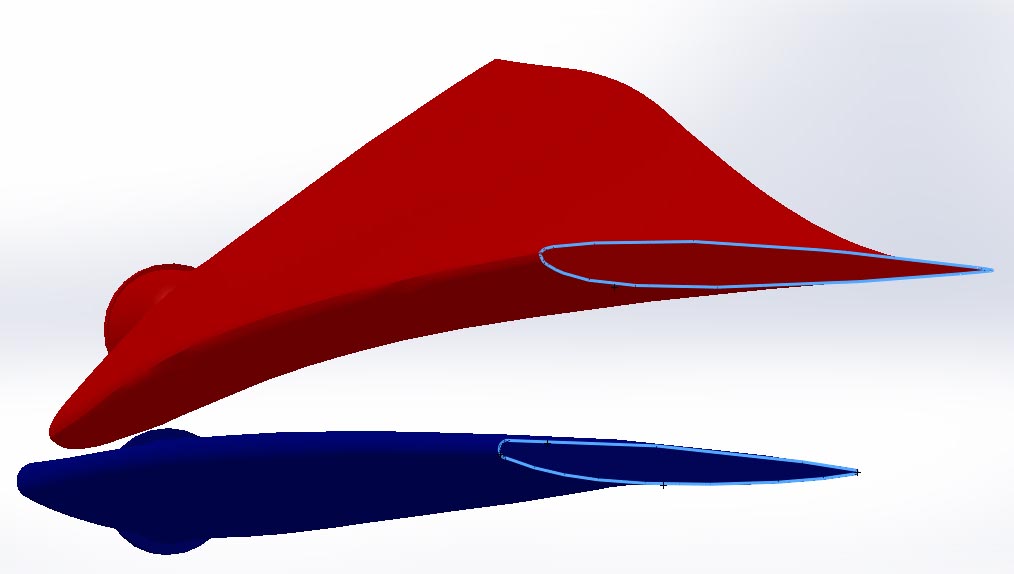

Maya FRP fan blade made of latest airfoil It is like an airplane wing. we do choose the most advanced airfoil possible for the fan to provide maximum efficiency. by this, we have achieved superior performance which is far ahead in the FRP fan industries. our blade is very robust in construction and designed for 7-10 times of operating load. we also provide superior wear resistance material to maintain surface stability for a long period. which prevents efficiency deterioration. Recently we have developed a special series in FRP fans in which we are providing state of the art fans in fiber-reinforced plastic. we are using this superior epoxy material for the blade tip speed of up to 22000 FPM

This FRP material is having some of the very charismatic property. it is very much possible to produce any complicated shape with ease. thus provide economical solution some of its special features are and listed below –

- High strength at low weight.

- Good impact, fatigue, and Tensile Strength (Ultimate)

- Excellent environmental resistance.

- Excellent chemical and corrosion resistance.

- Good thermal insulation.

- Better life of the entire ventilation fan system due to low assembly weight.

- Low moment of inertia help for the selection of optimum motor. It reduces overdesign due to higher starting torque thus motor operates under a better range of efficiency.

Fan Hub / Boss

Hub used in FRP fans is heavy in construction. In this we are using heavy thickness mild steel plate, cast iron, or Aluminum clamp and stainless steel hardware. Which provides long life. We are coating all mild steel parts with a heavy thickness of zinc.

Note – Optionally we also provide customize hub/Boss on special demand of the customer. Like caste hub boss, Spider Type Fabricated hub, etc.

Taper Locking

in most of our mine ventilation fan hub, we preferred to have a taper locking arrangement. This is provided with several types of different locking arrangements. Which proven in the field these taper lockings made of Cast iron or stainless steel.

FEW OF OUR PRESTIGIOUS FRP FANS CUSTOMER

Frequently Asked Question

List of application where we can use FRP fans?

Following are the few major application

- Cooling tower fans

- Condenser Fans

- Mining Fans

- AHU Fans

- HVAC fans

- Humidification and dehumidification

- Exhaust Fans

- Ventilation fans

- Air circulator

- Air washer Fans

- Tea wethering fans fans

- Wind tunnel fans

- ID fans and FD fans

- Tiunnel ventilation fans and many more

These are not the only list we have the solution for any king of mine exists in mankind.